Power Engineering

- Expertise

- Power Engineering

We develop and produce a wide range of solutions for regulation several different types of motors, heating elements and heat sources. In addition to the traditional systems such as triac-regulators and potentiometers our team of engineers have developed our own range of both 1-phased and 3-phased frequency inverters for power systems for regular electro motors and compressor motors in e.g. heat pumps etc.

All our frequency inverters are developed by our team of electro engineers in Denmark and are afterwards produced in our Danish factory or in one of our European subcontractors’ factories.

Our development team has a long and broad experience with electrical engineering for regulation of electro motors. They carefully consider the power systems engineering to obtain the best possible efficiency with the lowest possible energy loss.

In our online catalogue you find a range of frequency inverters for smaller ventilators and motors (370W, 750W and 1,5KW). These inverters are all part of the model series E 1045 and are controlled either by ModBus interface, 0-10V signal or potentiometer. They are supplied in a sturdy metal enclosure with cooling ribs. If mounted correctly the do not need any active cooling.

We have 2 model ranges in our standard solution of frequency inverters for compressors. These standard models are ready to be used of shelf for a range of compressor models as they are already tuned for the motors in these models.

However, you may often have specific requirements to the design and the inverter or the cold plate / cooling ribs, or you may be using a special compressor. Therefore, many of our larger customers have one of our standard models adapted or have their entirely own inverter engineered to fit their specific project.

The current range of standard frequency inverters for compressors consist of the model series 1045 and 1145, both with ModBus interface and the possibility of 0-10V signal input.

The current range of standard frequency inverters for compressors consist of the model series 1045 and 1145, both with ModBus interface and the possibility of 0-10V signal input.

The frequency inverter series 1045 is available for compressor motors of 1,5KW and 2,0KW. They are supplied in a sturdy metal enclosure with cooling ribs, which mean that when mounted correctly passive cooling will be sufficient. Different models determine which motor profiles are available for that model. The motor profile is then selected by use of dipswitches on the inverter. The 1045 models are controlled by either the ModBus interface or a 0-10V signal.

See the 1045 models for compressors here. Click motor profiles to learn which compressors motor profiles are tuned and for which 1045 model.

Frequency inverter series 1145 is available for compressor motors of 2,0KW and 3,0KW. They are supplied in a sturdy metal enclosure with cooling ribs, either placed crosswise or lengthwise the inverter. This provides more flexible mounting options and if mounted correctly passive cooling will be sufficient. Motor profile is easily selected by setting the dipswitches on the inverter.

The 1145 models are controlled via ModBus interface. As an additional purchase you can buy an add-on print for the inverter which makes it possible to use 0-10V control signal.

See the 1145 models for compressors here. Click motor profiles to get a list of compressor motors which the inverter 1145 is tuned for.

If the standard solutions do not fit your requirements, just contact our sales team. You can then in cooperation with our engineers find the right power solution and placement to obtain the best efficiency and performance conditions. Our experience can help your project to obtain the optimal solution.

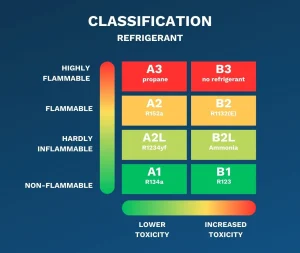

Are you using A3 refrigerant such as propane, R290 in your solution it is no problem.

Besides adapting our standard inverter series 1045 and 1145 we have also developed 1-phased and 3-phased inverter platforms which we can adapt to perfectly fit your tasks. Most times we can then obtain a higher efficiency for exactly your product and you get a uniquely adapted inverter which are solely produced for your use.

Since 1969, we have been supplying electronics for control, regulation and control to quality-conscious companies

Get important information about products which get you ahead of your competitors, the market, technical stuff and much more. All for free and just 4-6 times a year.

LS Control A/S | Copyright © 2022 All rights reserved.