Elforsk Ventilation project

- Cases

- Elforsk Ventilation project

In collaboration with the Danish Technological Institute, Lind & Risør and Lindab,

we have carried out an Elforsk PSO-funded project to investigate the new possibilities in BR 2018 Low Energy Class 2020 for demand controlled and air diversion.

New and energy renovated single-family homes are dense. Therefore, single-family homes built after 2010 with natural ventilation are rarely seen. The requirement for energy consumption (BE18 energy frame calculation) has a part in the choice of ventilation solution.

This case was carried out in a Lind and Risør demonstration housing of approx. 200m2.

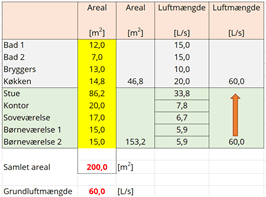

In living quarters as well as the dwelling in total, there must be an outdoor air supply of at least 0.30 L / (s * m2) heated floor area. The practical interpretation of the requirement is shown in the table below, which shows an example of fulfillment of BR 2018 low-energy cluster 2020 in the demonstration home.

However, it may be necessary to increase the air volume in bedrooms or children’s rooms to comply with the basic functional requirements.

It is also permitted to reduce the outdoor air supply to 0, 15L / (s * m2) for a longer period throughout the day, if the home is not in use. However, it requires that the ventilation system when measuring is able to regulate the outdoor air supply satisfactorily in relation to air quality and humidity conditions in the home. It must be ensured that no moisture problems occur that can lead to mold and that the CO2 level is at an acceptable level (equivalent to approx. 1000ppm).

It is a prerequisite for demand-controlled ventilation that there are sensors that can determine with high certainty whether there are people present in the home even if they are inactive, e.g. sleeping. Manual ventilation is therefore not considered sufficient for demand-controlled ventilation.

In addition, a number of requirements are set for ventilation in shower and toilet rooms as well as kitchens. For heat recovery, electricity consumption for air transport etc. Read the entire report, etc. on Elforsks website

In order to achieve the correct control of the ventilation system, we at LS Control as our starting point have chosen an already developed control unit which we could software-adapt to the unique requirements of the project for achieving precise control of the air supply. The control was programmed with the algorithms set up by the project in relation to obtaining air supply and combined with our standard duct sensors for measuring CO2 and moisture in the exhaust air and moisture in the supply air. These sensors are set up just before the ventilation system on the supply and

the exhaust side and provides information to the controller whether to turn the air supply in the home up or down. The sensor values also determine very precisely whether there are occupants in the house, as these will emit both moisture and CO2, which are measured in the exhaust air. Since the project also stipulates that the bedroom is considered to be the potentially most stressed room, a wall-mounted CO2 sensor is also installed 1.5m above the floor in the bedroom, thus providing the system with information about the load in this room so the air supply for the bedroom can be separately increased or decreased. This project has chosen to use a standard wired wall sensor, but we also have wireless wall sensors. Most standard sensors from LS Control can be used in installations with ModBus protocol.

The selected LS Control control also has a connection to the Internet for professionels to monitore and get alarms in the event of faults and need for filter change. An app makes it possible for the residents of the home to follow indoor climate conditions, such as CO2 and humidity levels in the home.

LS Control control with LS SmartConnect Center ensures that the air supply is precisely controlled, so that air quality requirements are met regardless of load in relation to humidity and CO2 level. LS SmartConnect Center makes it possible to remotely monitor the ventilation system and adjust the regulation of the system without disturbing the residents of the home. Likewise, any faults in the system will give an alarm on the remote monitoring and can in many cases be corrected without physical access to the ventilation system in the home. When it is time for a filter change, the system will via LS SmartConnect Center give an alarm and a new filter can be sent to the residents for replacement. Or a service technician can bring this and any other parts for repair and maintenance by agreement with the residents of the home. Thus, the ventilation in the house is automated to such an extent that it provides minimal disturbance to the residents.

When, as in this project, the starting point is an already developed control unit, both the development price and time are reduced. It is thus possible to get its finished product on the market faster and more cost-effectively.

Contact us for further information on customized ventilation controls and sensors for ventilation systems to meet BR2018 Low Energy Class 2020.

Since 1969, we have been supplying electronics for control, regulation and control to quality-conscious companies

Get important information about products which get you ahead of your competitors, the market, technical stuff and much more. All for free and just 4-6 times a year.

LS Control A/S | Copyright © 2022 All rights reserved.